Understanding Vertical Concrete Wall Formwork Systems #

Wall formwork plays a crucial role in shaping and supporting vertical concrete structures such as retaining walls, basement walls, and infrastructure partitions. These temporary systems ensure that concrete elements maintain their intended shape and alignment until the material has set and achieved sufficient strength.

What is Wall Formwork? #

Wall formwork is a temporary structure designed to mold and support vertical concrete elements during the curing process. It is essential for projects requiring precise, stable, and safe construction of walls in various settings, from infrastructure to commercial and industrial buildings.

Types of Wall Formwork #

At Sucoot, two main types of wall formwork are provided to address diverse project requirements:

-

Double-Sided Wall Formwork: Commonly used for retaining walls, this system employs two vertical panels held together with tie rods and support frames, ensuring stability and alignment during concrete pouring.

-

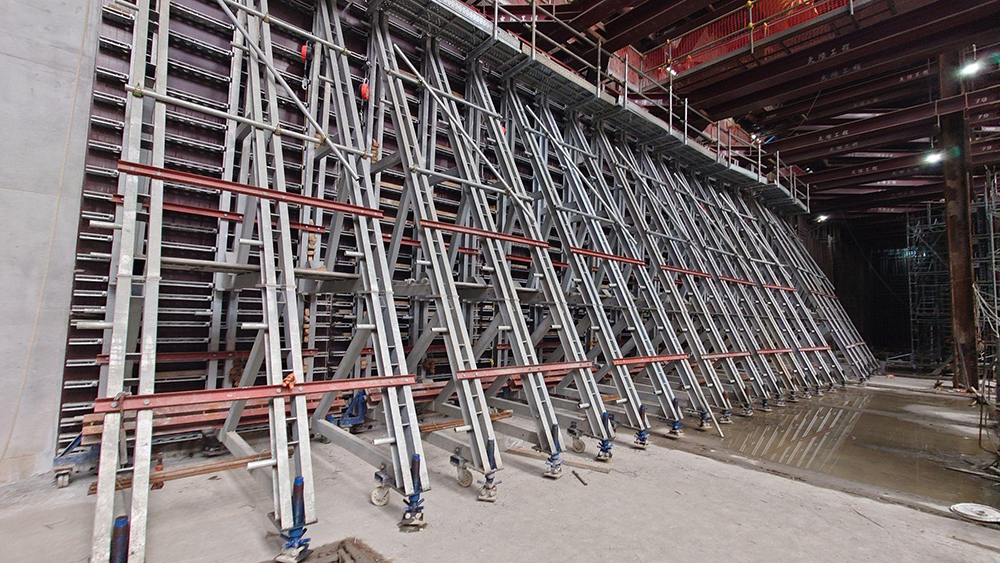

Single-Sided Wall Formwork: Ideal for applications such as basement perimeter walls or subway station walls, this system utilizes ground-anchored J-Bolts and robust support structures to withstand the lateral pressure of fresh concrete.

Structure and Key Components #

Sucoot’s Wall Formwork System is composed of four essential groups of components:

-

Forming Surface — Plywood

- The quality of the plywood directly influences the final appearance of the concrete wall surface.

-

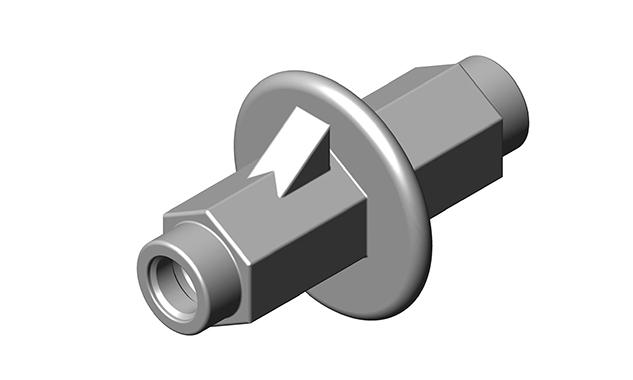

Fixing Components

- Tie Rods, Top Beams, and Base Beams work together as a unified fixing mechanism.

- The Form Tie System connects and clamps the Top and Base Beams to the plywood panels on both sides, creating a locked-in structure that resists the intense lateral pressure of fresh concrete.

- Top Beam and Base Beam serve as main or secondary bearers, providing stable horizontal support across the formwork height.

-

Supporting Structure

- Depending on the wall’s height and thickness, each project faces different levels of lateral pressure from freshly poured concrete.

- To balance formwork stability and cost, Sucoot configures the appropriate support system—using Spindle, Base Beams, or Triangle Strut Frames—tailored to the structural demands of each wall design.

-

Working Platform for Concrete Pouring

- A safe and stable platform is mounted on top of the wall formwork system, giving workers access to the upper section of the wall for concrete pouring operations. This integrated platform enhances job site safety and efficiency.

Engineered for Precision and Efficiency #

- Vertical Precision: Sucoot Wall Formwork is engineered for civil infrastructure, ensuring precise alignment and robust support for straight, secure walls with every pour.

- Tailored Configurations: From double-sided to single-sided systems, every tie rod, bearer, and support spacing is calculated to ensure safe, efficient, and single-pass pours.

- Built for Movement: The modular design allows for full-lift relocation, enabling entire setups to be repositioned without dismantling, accelerating project timelines.

The SUCOOT Base Beam/Soldier Beam #

The Base Beam/Soldier Beam is a versatile component suitable for various applications:

- Bridge Viaducts: Functions as a primary or secondary bearer for inner/outer formwork and wing form support.

- Slab, Beam, and Wall Formwork: Serves as a main or secondary bearer in different formwork configurations.

- Large-Span Structures: Accommodates large spans, offering cost savings in formwork support and concrete pouring.

- Lateral Support: Provides stable lateral support at any height, ensuring structural stability.

Application Areas #

- Infrastructure Projects: Bridges, viaducts, culverts, tunnels, and other large-scale developments.

- Industrial Facilities: High-tech factories, steel mills, and power plants.

- Commercial and Residential Construction: Ideal for forming robust columns, walls, and slabs.

Project Highlights #

Tainan Railway Underground Project – C211 & C214 Sections

Tainan Railway Underground Project – C211 & C214 Sections

Taipei MRT Circular Line North Section – Contract CF680C

Taipei MRT Circular Line North Section – Contract CF680C

Taoyuan Longtan Factory Basement Single-Sided Wall Formwork

Taoyuan Longtan Factory Basement Single-Sided Wall Formwork

Chih-Deh Factory – Double-Sided Wall Formwork

Chih-Deh Factory – Double-Sided Wall Formwork

Industry Applications #

Related Products #

Contact and Further Information #

For more details or to discuss your project requirements, please contact us.

Civil Engineering

Civil Engineering High-Tech Industry

High-Tech Industry Base Beam

Base Beam Top Beam

Top Beam Triangle Strut Frame

Triangle Strut Frame Form Tie System

Form Tie System Water Stop

Water Stop