Innovative Modular Bearer for Formwork Systems #

Sucoot’s Top Beam is engineered as a modular bearer component, crafted from SGH490 high-strength galvanized steel. This design ensures exceptional resistance to rust, deformation, and mechanical fatigue, making it a reliable choice for long-term use in slab, wall, and column formwork systems. The Top Beam is securely fixed to plywood using self-tapping screws or steel nails, providing a stable and robust load-bearing surface.

Key Features #

-

High-Strength Material with Anti-Corrosion Protection

Manufactured from SGH490 galvanized steel, the Top Beam resists warping, rust, and fatigue, even under demanding construction conditions. -

Eco-Friendly & Economical

The Top Beam is fully recyclable and offers a high residual value, supporting contractors in meeting environmental performance goals and reducing material waste. -

Extended Lifespan

With a service life at least 2.5 times longer than traditional wooden beams, the Top Beam minimizes replacement cycles and delivers long-term cost savings. -

Flexible Length Options

Available in standard lengths from 1.2m to 4.8m (in 300mm increments), with custom sizes available upon request to suit diverse project requirements.

Technical Specifications #

| Property | Symbol | Value | Unit |

|---|---|---|---|

| Section | — | H:135 × W:50 × T:2.3 | mm |

| Minimum Section Area | An | 5.6 | cm² |

| Average Weight | Uw | 5.5 | kg/m |

| Elastic Modulus | E | 200 | GPa |

| Yield Stress | Fy | 365 | MPa |

| X-axis Moment of Inertia | Ixx | 175.4 | cm⁴ |

| X-axis Section Modulus | Zxx | 26.0 | cm³ |

| Allowable Bending Moment | Max | 5.5 | kNm |

| Allowable Shear Force | Vax | 17 | kN |

- Material Certification: Each beam is produced from SGH490 structural steel, with mill certificates verifying chemical composition and tensile strength.

- Performance Data: Load testing is conducted to ensure reliable performance for real-world engineering applications.

Application Scenarios #

The Sucoot Top Beam is suitable for a wide range of construction and infrastructure projects, including:

- Bridge Viaducts: Functions as a primary or secondary bearer for inner/outer formwork and wing form support.

- Slab, Beam, and Wall Formwork: Serves as the main or secondary bearer in various formwork systems.

- Large-Span Structures: Designed to accommodate large spans, offering cost savings in formwork support and concrete pouring.

- Lateral Support: Provides stable lateral support at any height, enhancing structural stability.

Industry Applications #

- Infrastructure Projects: Bridges, viaducts, culverts, tunnels, and other large-scale developments.

- Industrial Facilities: High-tech factories, steel mills, and power plants.

- Commercial & Residential Construction: Ideal for forming robust columns, walls, and slabs.

Project Highlights #

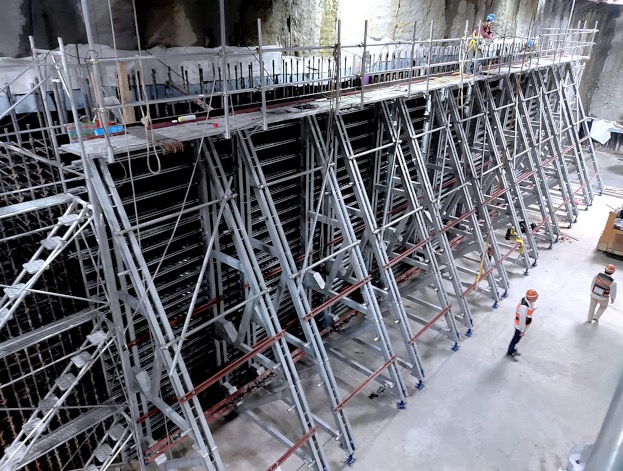

Taichung Central Taiwan Science Park South Access Road – Dajia River Bridge & South Approach Project

Taichung Central Taiwan Science Park South Access Road – Dajia River Bridge & South Approach Project

Tainan Railway Underground Project – C211 & C214 Sections

Tainan Railway Underground Project – C211 & C214 Sections

Taipei MRT Circular Line North Section – Contract CF680C

Taipei MRT Circular Line North Section – Contract CF680C

Taoyuan Longtan Factory Basement Single-Sided Wall Formwork

Taoyuan Longtan Factory Basement Single-Sided Wall Formwork

Chih-Deh Factory – Double-Sided Wall Formwork

Chih-Deh Factory – Double-Sided Wall Formwork

Chang Chun Factory

Chang Chun Factory

Junding Oil Tank Construction

Junding Oil Tank Construction

Related Products #

Industry Focus #

For more information or to discuss your project requirements, please contact us.

Base Beam

Base Beam Wall Formwork

Wall Formwork Column Formwork

Column Formwork Bridge Superstructure Formwork

Bridge Superstructure Formwork Slab Formwork

Slab Formwork Civil engineering

Civil engineering High-tech

High-tech