Innovative Approaches to Slab Formwork in Modern Construction #

In the realm of high-tech construction—such as semiconductor fabrication plants, cleanrooms, and precision manufacturing facilities—waffle slabs have become a preferred floor system. These slabs are engineered to span long distances, minimize floor vibrations, and support the substantial weight of heavy production equipment.

At Sucoot, our slab formwork systems are designed to meet these rigorous demands, enabling efficient pouring of thick, heavy-duty slabs even at heights of 5–10 meters above ground level.

Understanding Slab Formwork Requirements #

Waffle slabs typically range from 600 to 1200 mm in thickness and possess a much higher self-weight compared to flat slabs. This necessitates a shoring system that can reliably support heavy loads and long spans. Special attention must be given to the rigidity, bracing, and lateral stability of support towers, particularly when slab heights exceed 5 meters.

Structure and Key Components #

Sucoot’s slab formwork system provides a robust, modular foundation for casting in-situ slabs, especially for complex waffle slab designs. The system is composed of two main elements:

-

Formwork Bearer Components

- Top Beam: Galvanized steel bearers installed directly beneath plywood or waffle molds, serving as secondary bearers to evenly distribute the weight of wet concrete and construction loads.

- Base Beam: Positioned beneath the top beams as primary bearers, these provide vertical load transfer and alignment across wide bays.

-

Support Structure (Shoring Scaffolding)

- The entire formwork assembly is supported by Sucoot’s Ring Lock Scaffolding System, a heavy-duty shoring solution that ensures stability even at elevated heights. Depending on project needs, the system can be configured as slab shoring towers or as safe access platforms for crews. Its modular design allows for easy dismantling, reassembly, or relocation—ideal for large concrete pours and heavy reinforcement typical of waffle slabs.

Construction Benefits of Sucoot’s Slab Formwork #

-

Certified Strength and Height Adaptability

- The Ring Lock Scaffolding System enables the construction of strong, modular towers suitable for slabs at heights of 5–10 meters or more. All shoring scaffolding is tested and certified to EN standards by third parties, ensuring safety and reliability on site.

-

Efficient and Repeatable Setup

- Standardized Top and Base Beams allow crews to set up wide slab bays quickly and consistently, reducing labor time. Efficient erection methods, such as the Ground-Assembled Lifting Method and Reverse Assembly Method, further accelerate installation. The entire shoring system can be lifted and moved as a unit, enabling rapid transitions between slab bays without the need for complete disassembly.

-

Long-Term Durability

- All main load-bearing components—including shoring scaffolding, top beams, and base beams—are hot-dip galvanized for corrosion resistance. This ensures dependable performance and a service life exceeding 20 years under normal use.

Versatile Applications of the Base Beam/Soldier Beam #

The SUCOOT Base Beam/Soldier Beam is engineered for a wide range of construction scenarios:

- Bridge Viaducts: Functions as a primary or secondary bearer for inner/outer formwork and supports wing forms.

- Slab, Beam, and Wall Formwork: Suitable as a main or secondary bearer in various formwork configurations.

- Large-Span Structures: Accommodates large spans, offering cost savings in formwork support and concrete pouring.

- Lateral Support: Provides stable lateral support at any height, enhancing structural stability.

Ideal for Multiple Construction Sectors #

- Infrastructure Projects: Bridges, viaducts, culverts, tunnels, and other large-scale developments.

- Industrial Facilities: High-tech factories, steel mills, and power plants.

- Commercial and Residential Buildings: Robust solutions for columns, walls, and slabs.

Project Highlights #

Underground Railway/MRT: Tainan Railway Underground Project – C211 & C214 Sections

Underground Railway/MRT: Tainan Railway Underground Project – C211 & C214 Sections

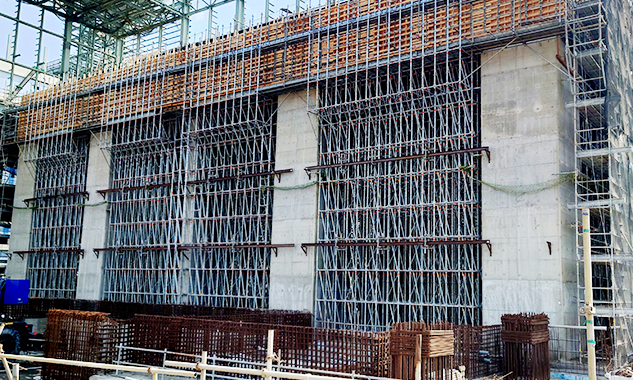

High-Tech Factories: Semiconductor Packaging Plant

High-Tech Factories: Semiconductor Packaging Plant

Power Plant: Taichung Power Plant

Power Plant: Taichung Power Plant

Power Plant: Mong Duong Power Plant

Power Plant: Mong Duong Power Plant

Power Plant: Tatan Power Plant

Power Plant: Tatan Power Plant

Industry Applications #

Related Products #

Contact #

For more information or to discuss your project requirements, contact us.

Civil Engineering

Civil Engineering High-tech

High-tech Base Beam

Base Beam Top Beam

Top Beam Ø60.2 T:3.2mm Shoring (Heavy Duty) Scaffolding

Ø60.2 T:3.2mm Shoring (Heavy Duty) Scaffolding